Transducer & Measurement shafts

From the precise strain gauge application to the fully calibrated, individual measuring shaft - we integrate measurement technology directly into your application. Robust, reliable and tailor-made.

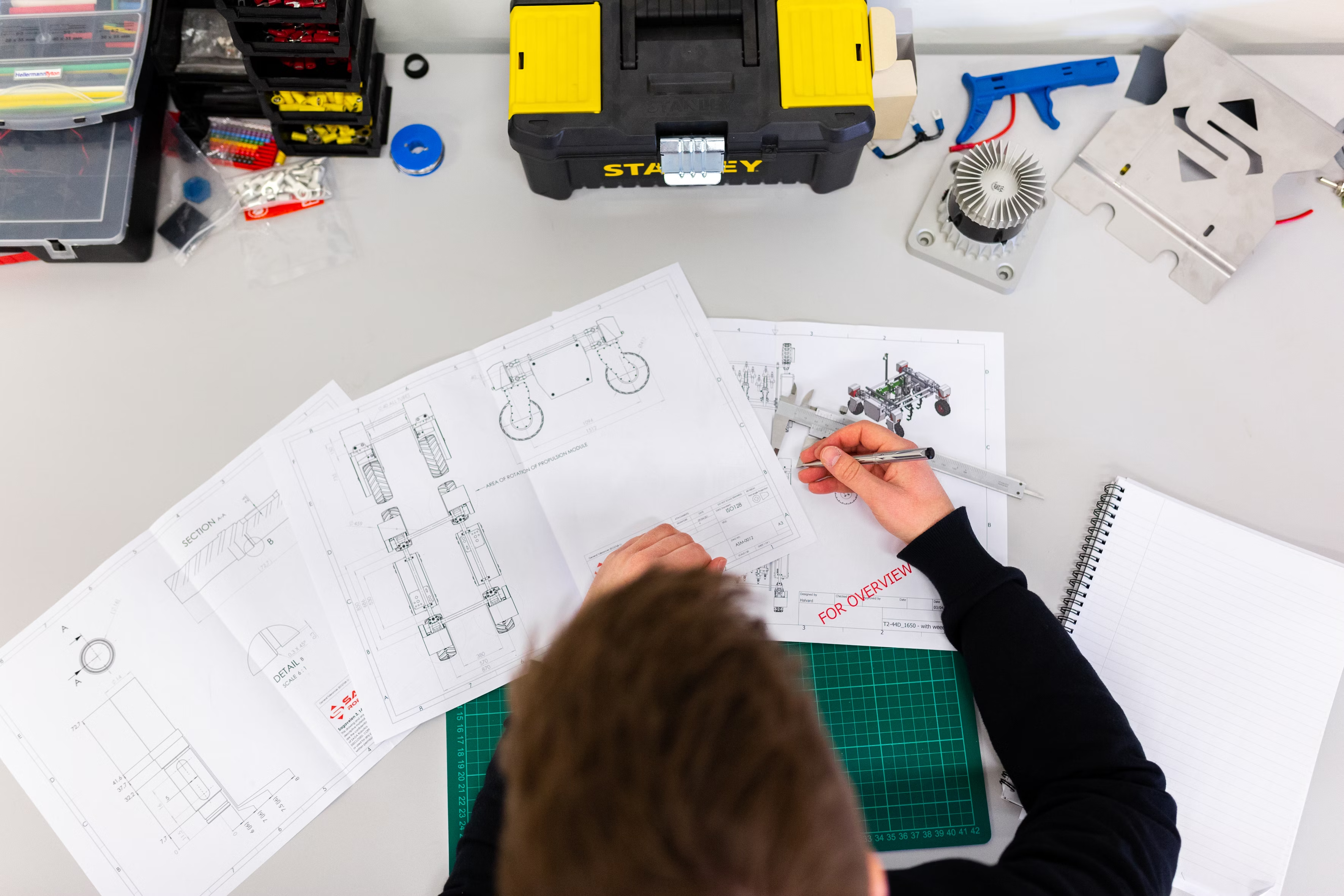

Measuring Shaft Application: Complete end-to-end service

We supply fully customized measuring shafts - installed, calibrated and ready for use in only 10 days. From the detailed analysis of your installation situation based on CAD data to the final validation and calibration on our test benches, we take care of the entire production process.

Whether you have limited installation space, high temperatures, dynamic loads or special environmental conditions - we develop the optimum, robust and ready-to-integrate sensor solutions for your rotating application.

-

Plug & Play: Calibrated and ready for immediate use

-

Quickly available: Complete measuring shaft in just 10 days

-

Tailor-made: Perfectly adapted to your requirements

-

Robust & reliable: For demanding environments

-

Expert support: Optional on-site support

Strain Gauge Application: Robust solutions for demanding measurements

We apply high-quality strain gauges (DMS) precisely to your components (e.g. tie rods, control arms) for reliable force and strain measurements under real-world conditions.

Our applications are protected by the innovative AXON APT (Adaptive Protection Technology) – an exceptionally durable, multi-layer protective enclosure.

AXON APT Protection Technology

The multi-layer fiberglass structure with elastic interlayers shields the DMS from external influences and mechanical stress without affecting the measurement.

-

Extremely Rugged: APT protection against oil, water, and debris (up to 160 °C)

-

Long-Term Stability: Reliable data even under continuous stress

-

Realistic Testing: Measurements without modifying the component

-

Precise Force Measurement: Direct capture at the source

Proven Across a Wide Range of Applications

Our flexible telemetry and application services provide reliable data for development, testing, and condition monitoring across a variety of industries.

Automotive

Reliable measurement technology for vehicle development and testing.

E-Mobility

Optimization of electric drivetrains and battery management systems.

Test Bench Technology

Precise data acquisition for component and system test benches.

Motorsport

Maximum performance and data reliability under racing conditions.

Industrial Plants

Monitoring and optimization of production processes.

Wind Power

Condition monitoring and efficiency improvement of wind turbines.

Aerospace

Sensor systems for testing and monitoring in aerospace environments.

Marine

Robust measurement solutions for maritime applications and shipbuilding.

Railway Technology

Data acquisition for rail vehicles and infrastructure systems.

PRODUCT OVERVIEW

Ready for your custom measurement solution?

Contact us to discuss your specific requirements and receive a tailor-made offer for our application services.